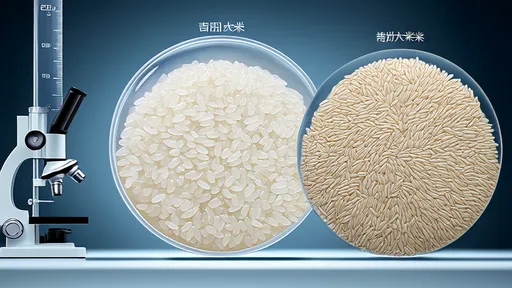

In kitchens across the globe, rice serves as a culinary cornerstone, yet its texture and behavior vary dramatically between cultures. A spoonful of sticky Japanese sushi rice clings together in perfect, bite-sized morsels, while a forkful of fluffy Basmati from India remains distinct and separate. This fundamental textural divergence isn't a matter of cooking technique alone; it is rooted deep within the grain's molecular architecture, primarily dictated by the content of a specific carbohydrate: amylose.

The story of rice's stickiness is a tale of two starches. Inside every rice grain, starch is composed of two types of glucose polymers: amylose and amylopectin. Amylose is a long, primarily linear chain of glucose molecules. These chains tend to align neatly and form tight, organized structures. When rice with high amylose content is cooked and subsequently cools, these linear molecules retrograde, or recrystallize, causing the grains to become firmer and separate. Amylopectin, on the other hand, is a highly branched, bushy molecule. Its structure prevents it from packing together tightly. Instead, it creates a gel-like, sticky network that causes rice grains to cling to one another. The ratio of these two molecules is the master switch controlling the final texture of cooked rice.

Generations of selective cultivation in East and Southeast Asia have favored rice varieties with specific culinary properties. In cultures where rice is often eaten with chopsticks or formed into shapes—like sushi in Japan, zongzi in China, or sticky rice with mango in Thailand—a cohesive, chewy texture is not just preferred; it is essential. This led farmers and, later, agricultural scientists to propagate strains naturally low in amylose and high in amylopectin. Iconic varieties like Japanese Japonica short-grain or Thai Jasmine rice are the result of this long history of selection for stickiness and tenderness, making them perfect for their traditional culinary roles.

The journey of rice to the West followed a different path. Introduced to the Americas and Europe, rice was often grown in new environments, like the Carolinas in the United States or the Piedmont in Italy. Consumer preferences also diverged. Western cuisines, where rice is frequently served as a side dish or pilaf, prized grains that were fluffy, separate, and non-clumping. This demand guided agricultural development toward long-grain varieties like Carolina Gold or Basmati types, which are inherently higher in amylose. This starch content allows the grains to remain firm and distinct after cooking, aligning with Western culinary expectations.

While tradition set the course, modern science has provided the tools to map it precisely. The difference in amylose content is not a random occurrence but is directly controlled by the rice's genetics. The key player is the Waxy (Wx) gene, which codes for the Granule-Bound Starch Synthase (GBSS) enzyme responsible for amylose synthesis. Different alleles, or versions, of this gene produce varying amounts of the enzyme. Rice varieties prevalent in Asia often possess alleles that result in low GBSS activity, leading to minimal amylose production and a glutinous texture. Conversely, Western long-grain rices typically have alleles promoting high GBSS activity, resulting in higher amylose content and non-sticky, fluffy grains. This genetic blueprint is the undeniable scientific basis for the textural divide.

The implications of this starch dichotomy extend far beyond the dinner plate. In industrial food production, the distinct functional properties of different rice types dictate their use. Low-amylose, sticky rice is indispensable for making rice-based snacks, crackers, and cakes where binding and molding are required. It is also the preferred choice for brewing sake and other rice wines, as its sugar conversion profile is ideal for fermentation. High-amylose rice, with its firm texture and lower Glycemic Index (GI), is often sought for health-conscious products and diets focused on slower glucose release. Its ability to remain firm also makes it the grain of choice for canned rice products and ready-to-eat meals where mushiness is undesirable.

Understanding the science of amylose empowers both home cooks and professional chefs. Selecting the right rice for a dish is the first and most critical step toward culinary success. Attempting to make a creamy risotto with a high-amylose rice like Parboiled will lead to disappointment, just as using sticky sushi rice for a pilaf will yield a gummy, clumped mess. The desired outcome—whether sticky, separate, creamy, or firm—is predetermined by the amylose content listed on the package, usually indicated by terms like short-grain, long-grain, or glutinous.

From a nutritional standpoint, the amylose content also influences the health profile of the rice. High-amylose rice generally has a higher resistant starch content. This type of starch resists digestion in the small intestine and ferments in the large intestine, acting similarly to dietary fiber. It is associated with several health benefits, including better blood sugar control, enhanced insulin sensitivity, and improved gut health due to its prebiotic nature. While sticky, low-amylose rice is often deliciously indulgent, those monitoring their blood sugar might find greater benefit in incorporating more high-amylose varieties into their diets.

The humble rice grain, a staple for billions, is a powerful testament to the interplay between culture, agriculture, and biochemistry. The simple act of choosing a bag of rice at the market is the culmination of centuries of selective breeding, driven by deep-seated culinary traditions. The invisible world of amylose and amylopectin molecules dictates a tangible and delicious reality on our plates. This understanding not only solves the mystery of sticky versus fluffy rice but also deepens our appreciation for this fundamental food, allowing us to make more informed and skillful choices in the kitchen every day.

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025